SCOUT content flow model

Contents

SCOUT content flow model¶

This model defines a structure and set of constraints which can be solved to track the flow of different “content types” through a material flow system. There are many ways that such a model could be formulated (within the constraints set by the principle of conservation of mass); this is one particular way, which has some convenient properties:

It can describe the main types of process that occur (involving mixing/assembly, conversion, and disassembly).

It can do something sensible if more specific information about processes is not available, making it easy to get started.

The constraints that are produced are well-posed, giving a unique solution.

Of course, it also has limitations, such as:

To ensure the constraints can always be solved, the process characteristics must be defined from upstream to downstream.

Conceptual structure of a process¶

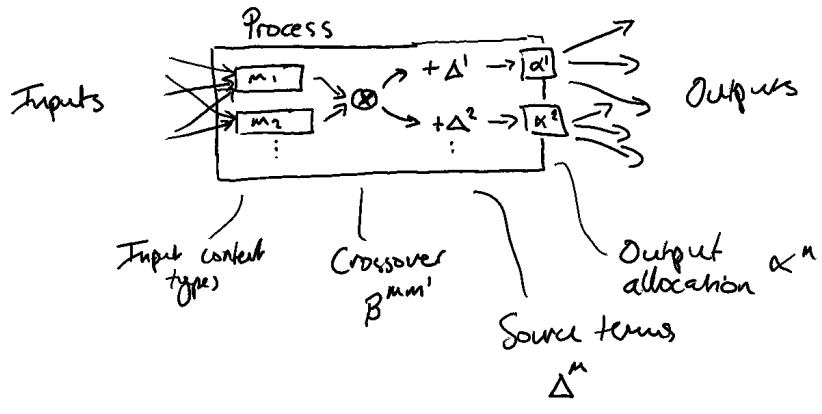

SCOUT stands for Source, Crossover, OUTput – these are the three types of parameter that are used to describe how different types of material pass through the process.

The crossover matrix \(\beta^{m m'}\) describes how content type \(m\) is transformed into content type \(m'\). If there is no transformation, this is an identity matrix.

The source terms \(\Delta^m\)\( describe how much new content of each type \)m$ is created (or destroyed) within the process. For most processes theses terms will be zero; at the beginning of the material flow model there must be some source terms to define a starting content of certain flows, otherwise the solution will simply be zero content everywhere.

The output coefficients \(\alpha_k^m\) describe how much of the content type \(m\) is sent to output \(k\). For most processes, these coefficients are set in proportion to the output mass flows, so that all outputs share the same content.

Basic constraint equation¶

TODO: details

Ensuring conservation of mass¶

TODO: explain the conditions that \(\alpha\), \(\beta\) must meet to keep conservation of mass.

Adjustments for imports and exports¶

TODO: explain how imports and exports are accommodated (they are assumed to have the same content as the main flows).

Higher-level interface to defining these coefficients¶

This model is quite flexible, but it has too many free parameters to be convenient as a means to specify the intended flow of different material types through the system.

We can describe three higher-level types of process behaviour that can be translated into specific values of \(\alpha\), \(\beta\) and \(\Delta\) for each process:

Output content

Output allocation

Content transformation

TODO: describe their definitions